Online:

+0086-21-56479076 / 59591768

Online:

+0086-21-56479076 / 59591768

Hotline

Hotline

1、All stainless steel production, especially suitable for GMP certification, food hygiene certification, anti-corrosion chemical products packaging, etc.

2、Touch screen man-machine interface, stable work, anti-interference, high weighing accuracy, convenient operation, intuitive. Packing weight can be adjusted stepless at any time, working state can be changed at any time, operation is convenient.

3、The filling adopts servo electric motor screw, which has the advantages of accurate positioning, high accuracy, high speed, large torsion distance, long life, adjustable rotational speed, good stability, and so on.

4、Mixing machine: low noise, long life, life-free maintenance of reducer motor.

5、The feedback weight tracking formula is designed to overcome the shortcoming of weight change caused by material specific gravity change.

6、Fully sealed air resistance glass stainless steel side compound box, material movement and movement at a glance, dust no leakage, fill the outlet dust suction device, protect the environment of the workshop.

7、Replacement of spiral accessories, can adapt to ultrafine powder to large particles and other materials.

021-56479076

A brief introduction to automatic canning production Line

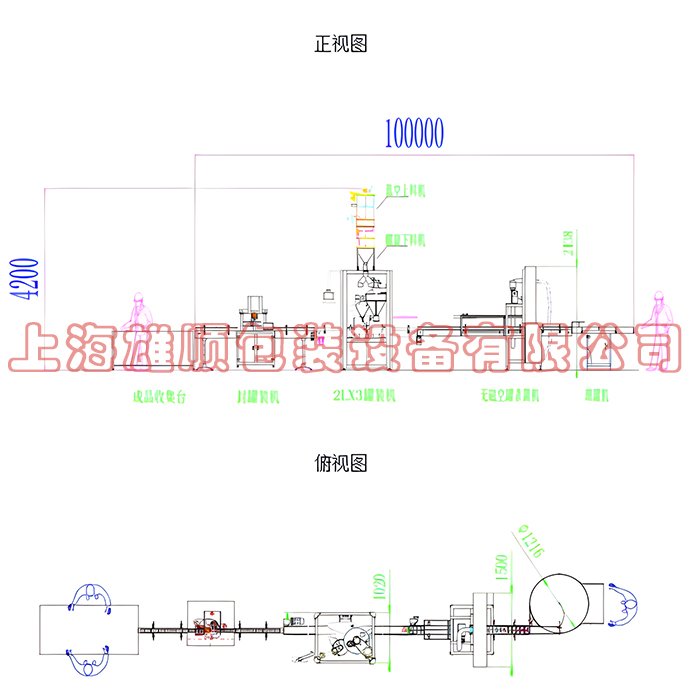

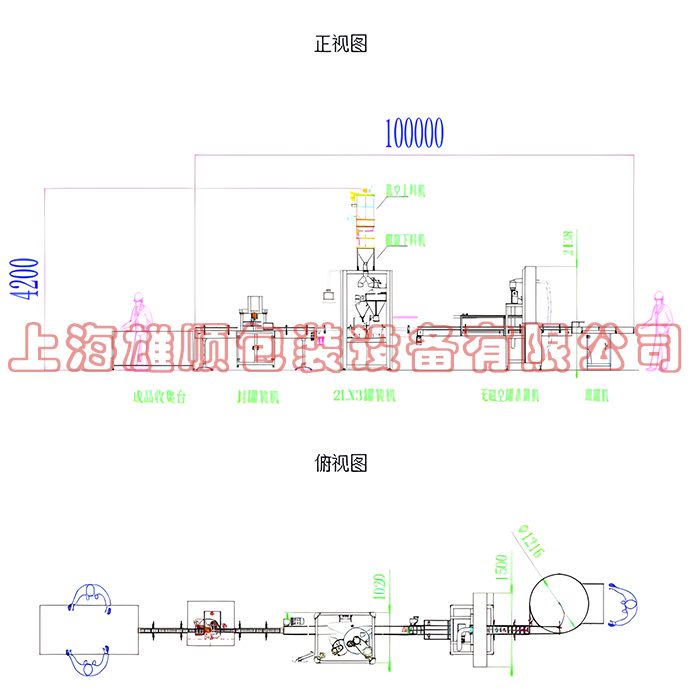

Front elevation

Full line drawing (for reference only)

I. XS-2LX3Canned automatic packaging machine

XS-2LX3Brief introduction of automatic canned Packaging Machine:

1、All stainless steel production, especially suitable for GMP certification, food hygiene certification, anti-corrosion chemical products packaging, etc.

2、Touch screen man-machine interface, stable work, anti-interference, high weighing accuracy, convenient operation, intuitive. Packing weight can be adjusted stepless at any time, working state can be changed at any time, operation is convenient.

3、The filling adopts servo electric motor screw, which has the advantages of accurate positioning, high accuracy, high speed, large torsion distance, long life, adjustable rotational speed, good stability, and so on.

4、Mixing machine: low noise, long life, life-free maintenance of reducer motor.

5、The feedback weight tracking formula is designed to overcome the shortcoming of weight change caused by material specific gravity change.

6、Fully sealed air resistance glass stainless steel side compound box, material movement and movement at a glance, dust no leakage, fill the outlet dust suction device, protect the environment of the workshop.

7、Replacement of spiral accessories, can adapt to ultrafine powder to large particles and other materials.

II.XS-2LX3Technical parameters of automatic canned packaging machine:

1、Measurement mode: two times after weighing, supplemental spiral rotary filling.

2、Container size: cylindrical container φ 50-180mm height 50-350 mm

3、Weight of packing: 100-2000g

4、Packaging accuracy:≤±0.5g-±1.5g

5、Packing speed:15—50Can/m

6、Power supply: 380V three-phase (or custom single-phase 220V) 50—60Hz

7、Whole machine power:3.5Kw

8、Air pressure:6—8Kg/Cm2

9、Gas consumption :0.2m3 /min

10、Whole machine weight:700Kg

11、The main material is 304 stainless steel.

III.Leading feature:

Double head filling, main filling and supplementary filling to ensure high tank accuracy.

Servo and turntable system control tank, accurate positioning, high speed.

Servo motor and servo drive control screw with stable performance and high precision.

All stainless steel structure; horizontal open box (inside and outside polishing), easy to clean.

PLC control, touch-screen man-machine interface display, easy operation.

The weighing system with high reaction speed ensures the realization of high tank speed and high precision.

The filling head is equipped with the handwheel to adjust the height, so that the external canister can be easily realized.

Equipped with dust removal device, connected with negative pressure pipe, no dust pollution environment.

Horizontal straight line structure, small area, easy to clean.

Fixed screw mounting structure without metal contamination when canned.

flow of work:Inlet can → Hold can → Vibrate → Metering filling →Weighing feedback → Supplementary filling → Outlet can.

V.The whole machine physical drawing (including the IPC interface picture):

Double end supplemental can loader Horizontal conveyer (auxiliary can loader)

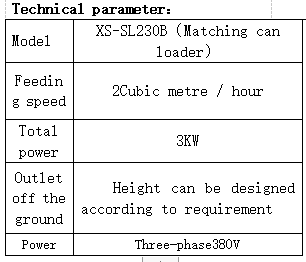

II.Vacuum feeder:

Brief introduction:

The vacuum feeder produced by our company is a new product developed on the basis of the extensive absorption of similar products at home and abroad. At present, it is the most advanced, ideal and perfect vacuum conveying equipment for powder, granular and powder aggregate mixtures in China. The vacuum feeding machine can automatically transfer all kinds of materials to the hopper of the equipment such as bin, packing machine, injection molding machine, pulverizer and so on, and can also directly transfer the mixed material to the mixer (such as V-type mixer, two-dimensional mixer, etc.) In the three dimensional mixer), the labor intensity of workers is reduced, and the problems of dust spillover during feeding are solved. The pharmaceutical factory and the food factory pass the GMP certification to promote cleanliness. The preferred equipment for civilized production。

Vacuum feeder consists of vacuum pump (no oil, no water), vacuum hopper, filter (polyester-coated filter, PE filter, 316L stainless steel filter or titanium metal filter), compressed air backblow device, pneumatic release door device, Material level automatic control device, stainless steel suction nozzle, conveying hose, etc., the whole system is of reasonable design and exquisite manufacture.

三、XS-SJ Empty tank sterilizer

Disc type empty tank cleaning and disinfecting machine

Brief description:

Disc empty tank cleaning and disinfection machine is the latest product developed and exclusively produced by our company. It is a combination of empty tank conveying, purifying, blowing, cleaning, ultraviolet sterilization and disinfection. Suitable for purifying, cleaning and sterilizing containers of glass, metal, plastics and compound materials.

Characteristics:

1. One machine has many functions, simple and compact structure, small area and high bactericidal efficiency.

2, no magnetic transfer can, empty tank inside and outside disinfection thoroughly clean.

3. It simplifies the "disadvantage" of container conversion and improves the efficiency of production.。

Technical parameter:

1、Cleaning speed: ≤ 45 cans / min (502 milk powder can, change the fixture can realize the cleaning and sterilization of many bottles) frequency conversion speed regulation.

2、Applicable container specification:φ76-130mm 高80-200mm

3、Speed reducer power: 1.1 KW (excl. suction, hairdryer) UV lamp: 25W × 7

4、Power supply:Three-phase380V 50HZ

5、Size:2500×1510×2435mm

四、automatic sealing-can machine

1、Equipment Overview

Tank cap joint control device: when the tank body enters, the tank cap should be allocated accordingly, and without the tank, there will be no cap;

The operation panel design is reasonable and simple, convenient for adjustment and maintenance.;

High production capacity, high degree of automation, suitable for sealing production line equipment。

This equipment is the characteristic of our company according to a large number of customer feedback demand information, as well as the generally popular semi-automatic sealing machine on the market, the efficiency of the semi-automatic sealing machine is low, the staff operation difference is big, and the level of labor price is constantly rising. Our company's newest developed automatic can sealing machine with new generation technology;

This machine is the upgrade version of our semi-automatic tank sealing machine. It adopts the rotating principle of the tank body without rotating hob, and the machining precision is very high, and the sealing quality is superior to that of the domestic similar products.;

This machine is the upgrade version of our semi-automatic tank sealing machine. It adopts the rotating principle of the tank body without rotating hob, and the machining precision is very high, and the sealing quality is superior to that of the domestic similar products.。

Suitable for sealing of all kinds of tinplate cans, aluminum alloy cans, paper cans, etc.

Mouth, easy to operate, easy to learn, is the food, beverage, pharmaceutical and other industries of the ideal equipment。

2、Specification parameter:

Material: stainless steel

Canning number:1

Canister speed: 25-35 / min (depending on the height of bottle size)

Tank height:50-240mm

Applicable bottle diameter:35-126mm

Voltage:220V/380V 50/60Hz

Power:1.1KW

Weight:100KG

Size:3000(L)*900(W)*1800(H)mm

五、Bottle feeding machine:

Turntable diameter:1000mm

Tank handling capacity:80 Cans/min

Power supply: 220V 50/60Hz

Total power:0.18KW

Outline dimension:1400*1200*1200mm

Features: arrange the manually placed or unloaded cans into rows.

Tel