Online:

+0086-21-56479076 / 59591768

Online:

+0086-21-56479076 / 59591768

Hotline

Hotline

Eye drops filling-stoppering-capping machine applicable to the pharmaceutical industry for the 2-30 ml bottle of liquid filling and sealing packing process, etc. The structure is reasonable, automatically unscramble bottle, filling and managing stoppers, stoppering, loading caps, screw capping, high precision CAM indexer for uniform chart positioning, no clearance......

021-56479076

XS-DYJ Eye drops filling-stoppering-capping machine

I.Overview:

Eye drops filling-stoppering-capping machine applicable to the pharmaceutical industry for the 2-30 ml bottle of liquid filling and sealing packing process, etc. The structure is reasonable, automatically unscramble bottle, filling and managing stoppers, stoppering, loading caps, screw capping, high precision CAM indexer for uniform chart positioning, no clearance, positioning accuracy; High precision piston pump (or peristaltic pump) filling, measuring accurate, adjustable, clean and maintenance is convenient , easy operation, no bottle no filling, no bottle no stoppering, no stoppers no capping function. Work surface with 304 high-quality stainless steel materials protection, contact with the liquid part is 316L quality stainless steel, the machine meet GMP requirements. The machine drive adopts mechanical transmission, drive accurately and smoothly, with low dissipation, work smoothly, stable production, etc, especially suitable for batch production enterprises.

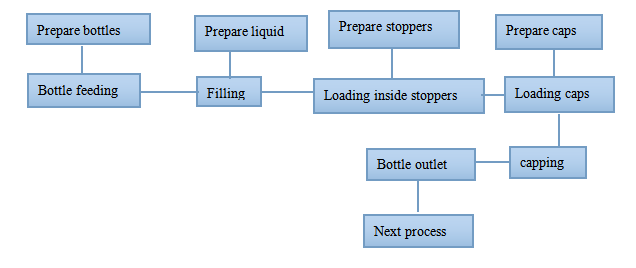

II.Working principle:

Ø Prepare materials:

Prepare enough bottles, inside-stoppers, outside-caps, and liquid medicine, inside-stoppers and outside-caps should be filled with vibration hopper rail and located in the position of inside-stoppers and outside-caps station.

Ø Bottle feeding: bottles are sent by the bottle feeding rotary table into the rail.

Ø Filling:

Bottles are sent by oscillation unscrambler bottle machine after tidying to the positioning disk, then again sent by positioning disk intermittent drive to filling, stoppering, loading caps, screw capping. Solution by peristaltic pump suction then transmission by silicone pipe, at the filling station again by the needle can be moved up and down automatically filling liquid into the bottle. The needle every time move up and down, then finish one time filling.

Ø Loading inside-stoppers:

Stoppers are provided by vibration hopper to the stoppering station, bottles are through rotary clearance to the stoppering station, through the optical fiber detection to control stoppered cylinder solenoid valve work signal to control the cylinder work so as to achieve the function of with bottle then stoppering, without bottle then not stoppering,stoppering plate using gravity principle design, avoid the spring or spring plate instability happens after long time use, so the stoppering is very accurate.

Ø Loading caps,screw capping:

The bottles with inside-stoppers are sent by the positioning disk to the loading caps,screw caps station, loading caps is the similar principle with loading stoppers,which is also done by the cylinder, capping is finished by the screw capping heads,The bottom of screw capping heads constantly rotating and overall do up and down movement, when the bottle stops at the right position, Falling-down screw cap heads wrap the caps then finishe the capping process.Screw cap body adopts the design of constant torque, according the bottle cap and bottle thread with torsion, to adjust the firmness of the screw cap after putting the caps in place can automatic sliding, achieve the goal of not wounded caps and bottles.

Ø Bottle outlet:

The bottles with caps then sent to the conveyor belt by the outlet bottle wheel,finally delivery to the of the machine, and entered into the next packaging process.

Note: 1.The machine USES unique loading stoppers fixed structure, accuratly.

No bottle no filling, no bottle no stoppering, not stoppering no capping function.

With urgent stop switch, automatic alarm when machine is out of order.

This machine with dust cover.

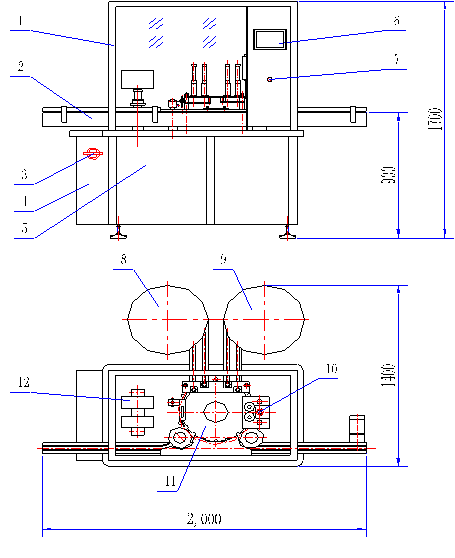

III.Shape structure chart:

Eye drops filling-capping machine structure diagram

1.Dust cover 2.Conveyor belt 3.Power 4.Electric box 5.Machine frame 6.The man-machine iterface 7.Emergence stop switch 8.Loading stopper hopper 9.Loading caps hopper 10.Screw cap device 11.Rotary disk 12.Peristaltic pump

4、Technical parameters and configuration:

Produce capacity:30-50 bottles/minute

Suitable bottles:2-30mL plastic bottles

Filling method:peristaltic pump

Filling heads:Single head

Metering precision:±1%

Loading stopper rate: ≥99%

Loading stopper heads:2 heads

Screw capping rate: ≥99%

Capping heads:Single head

Power: 2.5kw 380V 50Hz

Air supply: 0.3~04kfg/cm2

Air consumption: 10~15m3/h

Dimension: 2400×1300×1700

Tel