Online:

+0086-21-56479076 / 59591768

Online:

+0086-21-56479076 / 59591768

Hotline

Hotline

Overview: This machine integrating mechanical, gas into one as special equipment for the automatic sorting of plastic bottles and all kinds round bottles which are could be automatically straighten out and delivery. This machine outlet the bottles adopts stepless speed, speed smooth and reliable, easy to operate, in line with the requirements of GMP. This machine can use single, but also with other pharmaceutical machinery of bottled packaging production lines. This machine is widely used in pharmaceutical, chemical, food, health food and other industries, effectively reduce the labor intensity of operators, improve productivity and product standardization.

021-56479076

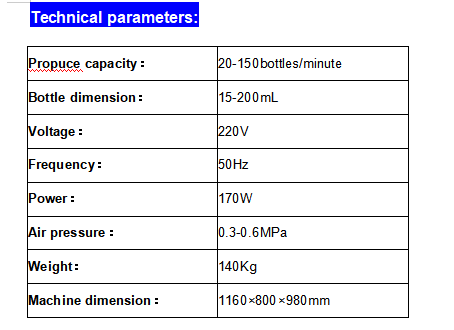

1.ZLB-A Automatic Unscramble bottle machine:

Application:

Overview: This machine integrating mechanical, gas into one as special equipment for the automatic sorting of plastic bottles and all kinds round bottles which are could be automatically straighten out and delivery. This machine outlet the bottles adopts stepless speed, speed smooth and reliable, easy to operate, in line with the requirements of GMP. This machine can use single, but also with other pharmaceutical machinery of bottled packaging production lines. This machine is widely used in pharmaceutical, chemical, food, health food and other industries, effectively reduce the labor intensity of operators, improve productivity and product standardization.

Main Characteristic: This machine is mainly consists of storage bottle, unscrambler bottle, sifting, outlet bottle and pneumatic device etc, transmission part mainly machinery, motor with gear reduction electronic speed motor stepless speed regulation, and equipped with pneumatic device. A double insurance to unscramble bottle correctness.

The main movement of the machine is moving plastic bottles into store- bottle -box, automatic unscramble bottle after sifting plastic zone, by rotating bottle sorting, make the positive upright one by one into the bottle body in an orderly fashion to the next working procedure. The machine adapts to different produce speed requirements, running condition, the machine automatically unscramble bottle, which can realize automatic stop when filled bottles, lack of bottles automatically boot smooth function.

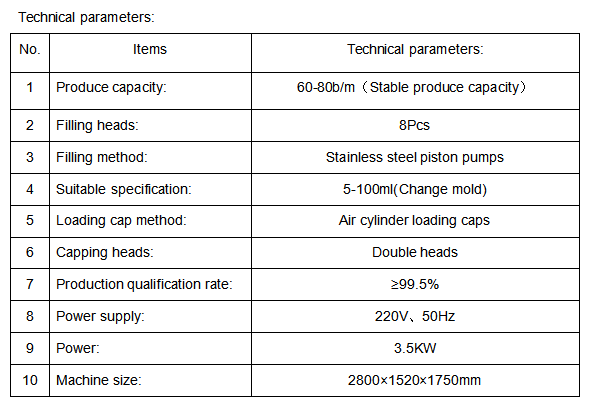

2、ZLB-A High speed spray filling rotary capping machine:

Spray filling capping machine: mainly used in pharmaceutical and cosmetics industry circular plastic bottles and glass bottle,loading cap and capping operation. The equipment adopts cylinder cap, clamping and positioning of die, simple and convenient replacement specification, mechanical transmission, accurate transmission, stable transmission, low loss, steady working, stable output, etc. Touch screen PLC intelligent control, simple operation, convenient man-machine dialogue; can be separated with the front-end machine line operation, especially suitable for mass production. The working table of this machine is protected by stainless steel material, the whole machine meets the requirements of GMP.

Operation principle of the equipment: bottle-spray filling capping machine: 1, The bottles are through unscrambler arranged and sent to the flat conveyor belt. 2. The conveyor belt runs the bottle to the set position to fill. 3. The filling is completed and the bottle is run through the conveyor belt To the turntable mold 4.Run to the set position, Optical fiber checks the bottle, the cylinder works to add the bottle to the bottle (no bottle will not be capped) .5, The bottle goes to the next station to tight screwing the cap. 6,The finished product is transported through the conveyor belt to the next process. (This equipment with the function of no bottle and no cap, the taut of the cap is adjustable, and the output is counted).

Performance review:

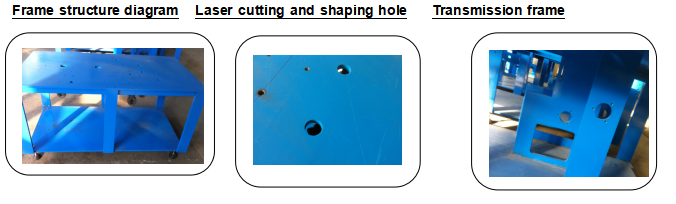

1.Frame structure:Structure using the overall steel frame (previously welded forming frame, easy deformation), nut positioning.Features: to prevent deformation of hard enforce,Surface coating anti rust paint.

Mechanical components:

Our application of materials, machining accuracy, heat treatment requirements and workpiece quality inspection are of vital importance. We spare any effort to keep improving the steady processing, all adopt the high-precision import processing center to process and shape, the material selects the superior in the middle to seek the superior, in the quality control, the strict up, ensures the stable high output of the long-term use of the machine.

Equipment frame: Carbon steel bottom plate use 1.2mm SUS304 steel plate,1.2mm stainless steel matte plate for mesa and SS304 stainless steel plate for vertical column,

Piping flexible part silicone rubber hose,

All pipes are automatically argon arc welding and all internal and external surfaces are mechanically or electronically polished,

All pipes in contact with the medium are of 316L material.

Tel