Online:

+0086-21-56479076 / 59591768

Online:

+0086-21-56479076 / 59591768

Hotline

Hotline

This scheme can meet all the requirements of GMP, safety, health and environment in the production, and mainly completes the labeling and coding functions of the product. The equipment adopts Siemens PLC control, Anchuan stepping motor drive, Emery drive roller, has the advantages of high speed, high precision, high stability, durability, flexible use, can greatly improve the production efficiency and save cost. The labeling machine produced by our company is mainly suitable for the circular (circumferential) labeling of products on various production lines in daily chemical, pharmaceutical, agricultural, health products, food, chemical, electrical and other industries, and can be matched with ink-jet printer and printer Synchronously print production date, batch number, validity period and so on when labeling. The machine adopts photoelectric detection and touch screen control (frequency conversion speed), has the advantages of accurate labeling and high precision, and has the advantages of no objects and no labeling, no need to move the head out of the electric eye touch screen control adjustment, and saves manual adjustment time. Automatic detection function;

021-56479076

SC-103B High speed round bottle labeling machine

(Pictures for reference only)

1.Summary:

This scheme can meet all the requirements of GMP, safety, health and environment in the production, and mainly completes the labeling and coding functions of the product. The equipment adopts Siemens PLC control, Anchuan stepping motor drive, Emery drive roller, has the advantages of high speed, high precision, high stability, durability, flexible use, can greatly improve the production efficiency and save cost. The labeling machine produced by our company is mainly suitable for the circular (circumferential) labeling of products on various production lines in daily chemical, pharmaceutical, agricultural, health products, food, chemical, electrical and other industries, and can be matched with ink-jet printer and printer Synchronously print production date, batch number, validity period and so on when labeling. The machine adopts photoelectric detection and touch screen control (frequency conversion speed), has the advantages of accurate labeling and high precision, and has the advantages of no objects and no labeling, no need to move the head out of the electric eye touch screen control adjustment, and saves manual adjustment time. Automatic detection function;

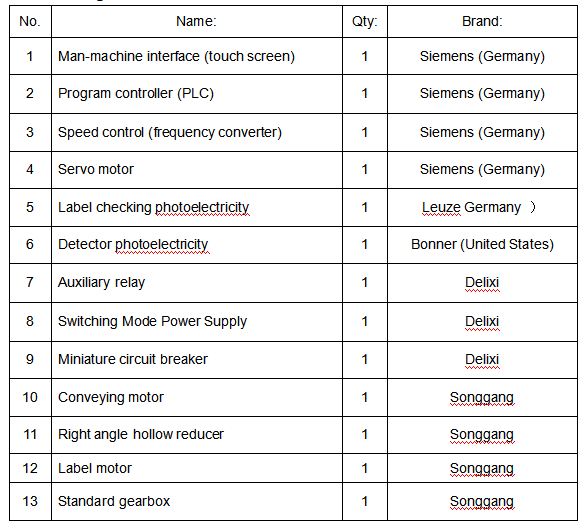

2、Main component:

1.Label feeder;

2.Stainless steel cabinet;

3.Chinese touch interface;

4.Electric control system

3、Technical parameter:

lLabeling speed : 50-260pcs/m(Depending on to the size of the label)

lLabeling accuracy :±1mm(Unaccounted for affixes and labeling errors)

lOut speed :3~35m/m

lConveyor belt speed:5~25m/minute

lMainframe direction :Left→right or right→left

lThe size of the affixed object:According to the customer's request

lDimension : About L2000×W1100×H1770 ( mm)

lApplicable label:Transparent / opaque label, semi-transparent; inner diameter of label roll φ 76.2mm, maximum outer diameter φ 340mm; width of label paper: 16 mm~200mm

lWeight : About 200kg

lPower supply : AC220V±5% 50/60Hz

lGas source : 0.4~0.7Mpa

lRelative temperature of working environment: 0~50℃

lUsing relative humidity: 15~90%

4、Functional characteristics:

lThe whole electronic control system is controlled by PLC. The Chinese touch interface is very convenient and intuitive.

lConveyor belt, bottle splitter, winding mechanism is driven by a single adjustable motor. Labeling head can be adjusted in multiple directions, easy to operate.

lThe sticker position and the stopper can be adjusted according to the size of the object, which can be used to label many products with the same machine.

lUsing the method of radio eye, it can ensure that the object can be detected stably without the influence of the color of the surface and the unequal factor of the reflection level, so as to ensure the stability of the label and no error.

lAll accessories including cabinets, conveyor belts, retaining rods and even small screws are made of stainless steel or aluminum profiles, free of rust and pollution, and ensure compliance with environmental requirements.

lAll the control components of the system have been strictly inspected and tested to ensure the stability and reliability of each function.

lThe working condition and malfunction of this machine have the function of reminding and warning, which makes operation and maintenance more convenient.

lThe system has the function of parameter manual and automatic setting. The automatic setting function can set the pre-exit length automatically, and can automatically set the pre-exit length to the best. It does not need to be manually set many times, saving debugging time.

Main configuration:

Tel